Miniaturizing Aluminum Electrolytic Capacitors for Power Applications

October 22, 2018

Preface

In recent years, mobile technologies and services of electronic devices have been rapidly advancing. To meet the market requirements for power supply/adapter miniaturization and weight reduction, Rubycon has focused extensive R&D on various capacitor products. Aluminum Electrolytic (AE) capacitors are generally large in size when compared to other electronic components and are therefore one of the key components to focus on for overall size reduction. In recent years, the market for LED lights and onboard electronic devices have expanded. Market requirements such as long-term reliability for high temperature capability along with performance guarantees for low temperature operation have increased. AE capacitors have a finite service life and are therefore one of the key factors in determining the overall life of your power supply. AE capacitors also have a low temperature degradation to consider. Considering the above-mentioned requirements solutions including life prolongation and low temperature operation have proven to be essential.

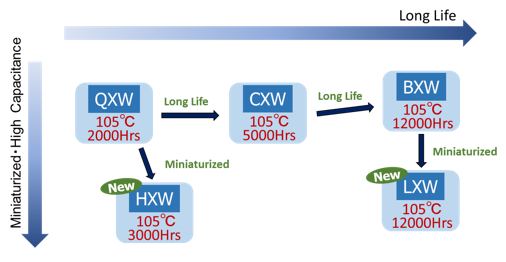

In order to meet such market requirements, Rubycon has developed and marketed various small-sized & high-capacity AE capacitors for power source input circuits. Up until now, our QXW Series was our base product for 105ºC in general applications. This series featured a relatively small-size to high-capacitance ratio. Our next development included our CXW and BXW Series which further expanded the performance and life capability. To further address the requirements for higher density we have developed the latest series (HXW) which was introduced in November of 2017 featuring a temperature range to 105ºC with extremely compact size and 2-3000 hour life. We followed this up in April of 2018 with the introduction of our LXW Series also a 105ºC capacitor but featuring the longest life of this product type with 10-12,000 hours (See Figure 1).

Characteristics of each Series

HXW Series have been developed for applications such as power supplies or adapters, and LXW Series has been developed for LED lights or other devices where higher reliability is essential. In order to realize miniaturization while maintaining the characteristics of conventional devices, both series have maintained the equivalent rated ripple current as prior series while achieving a reduction of approximately 20%. These series have abundant size options with thin profiles with diameters as small as 10mm and lengths to 60mm. We also offer < 30mm lengths which is popular for 1U server power supplies as well as 90 degree lead forming to horizontally mount the capacitor for a low profile height. With respect to low temperature operation, all products including our 500V rated can be used in the temperature region as low as -40ºC and, as a result of that, these series become usable in a broader application range. Table 1 gives an outline of HXW Series and LXW Series.

| HXW SERIES | LXW SERIES | |

|---|---|---|

| Category Temperature Range | -40 ∼ +105ºC | -40 ∼ +105ºC |

| Rated Voltage Range | 400 ∼ 500V | 400 ∼ 500V |

| Capacitance | 15 ∼ 270µF | 15 ∼ 220µF |

| Case Size | 10×30 ∼ 18×50 | 10×30 ∼ 18×50 |

| Endurance | 2,000 ∼ 3,000hr | 10,000 ∼ 12,000hr |

Table 1: Outline of HXW Series and LXW Series

This article introduces 3 key points such as Miniaturization, Low Temperature Characteristics and Life Prolongation which were focused as essential technical elements in R&D of HXW and LXW series.

(1) Miniaturization

AE capacitors are polarized electrolytic capacitors whose aluminum oxide layer formed on the surface of anode foil acts as dielectric and stores electricity. Etched surface of anode foil having microscopic pits enlarge the surface area of the anode foil. Etched and enlarged surface area enables AE capacitors to achieve significantly high capacitance compared with other capacitor types.

Capacitance of AE capacitors increases proportionally to the surface area of anode foil. For this reason, it is effective to further enlarge the surface area by increasing the etch pit density. However, with higher etch pit density, this causes elution of the aluminum which results in a loss of the material strength of the anode foil. As AE capacitors are being manufactured by cutting and winding of the anode foil, it is difficult in nature to cut and wind low strength anode foil when developing smaller-sized capacitors.

Rubycon has been developing in house our own manufacturing equipment and other process control in order to manufacture capacitors under optimal conditions helping to better match the characteristics/specifications of the products and material. Rubycon continues its long-standing research and development of cutting & winding technologies of large-capacitance aluminum. In the development of our HXW and LXW Series, Rubycon has successfully enabled to cut & wind the large-capacitance and lower-strength anode foil with high precision in order to commercialize the smallest-sized capacitors. Likewise, Rubycon has successfully developed higher-strength anode foils maintaining higher-capacitance versus conventional types. As a result of its diligent R&D in both products and material, Rubycon has succeeded in developing and marketing our HXW and LXW series which are the smallest in size without compromising the reliability.

(2) Low Temperature Characteristics Improvement

Electronic devices or power supplies are also considered for outdoor installations. In the colder seasons having a low temperature guarantee is necessary. Temperatures of -30ºC or lower are generally required. The challenge of an AE capacitor at such temperatures involves the electrolyte employed. Generally speaking, the electrolyte used inside can have a tendency to change from a liquid to solid state which can cause wide variance in ESR and capacitance characteristics. To meet such lower temperature stability without relying on the capacitor self heating, we have developed specialized electrolytes that are more stable and have a lower freezing point.

A while back, Rubycon upgraded our 450V, QXW series which can be used as low as -40ºC. Rubycon has applied this electrolytic solution to our HXW and LXW series which also can operate as low as -40ºC also including our 500 volt options.

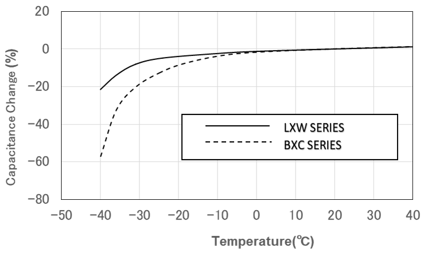

Figure 3 is a graph comparing the capacitance change rate of the two series at low temperatures. Our conventional BXC series exhibits a rapid drop of its capacitance at -15ºC and our LXW series using a newly developed electrolytic solution has an electric resistance value which is more stable in a low temperature environment- even as low as -30ºC.

(3) Life Prolongation

Capacitors used for power supplies of LED lights for example require stable and long-life characteristics. AE capacitors use electrolytic solution inside, which diffuses gradually through the seal material to finally reach an open (safe) end of life when the electrolyte eventually dries up. For that reason, it is indispensable to slow the diffusion of the solution as well as to reduce the deterioration of the solution itself.

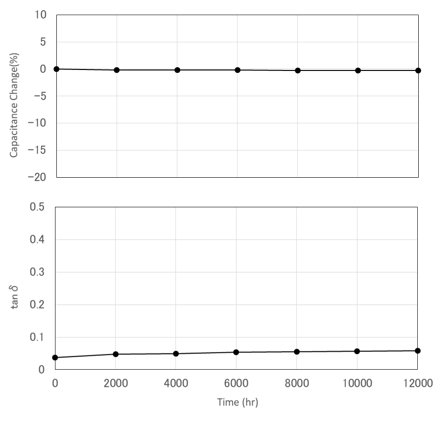

Rubycon has accumulated its know-how of electrolytic solutions development over 50 years and has a number of achievement records in the field of long-life characteristic improvement of capacitors for LED lights for example. Electrolytic solution of our LXW series have been developed with the objective of lower resistance value and higher stability of electric characteristics of the solution in the environment of longer time of use in a higher temperature. Figure 4 exhibits high temperature load test results (Rated Ripple Voltage Superimposed) of our LXW series at a temperature of 105ºC.Even after an interval of 12,000hrs it can be seen that there is not much difference in electric characteristics, which results in performance stability.

Our LXW series demonstrates excellent electric characteristics in low temperature environments as well as long-term reliability in a high temperature environment and thus the LXW Series is a remarkable invention for a broad range of environments.

Future Initiatives

Our HXW and LXW Series are the latest products which can be broadly used for a wide variety of applications by striking a balance of a size and electric characteristics. Rubycon is committed to continue its long-standing R&D activities for further miniaturization of capacitors by making the best use of the technologies acquired through the development of our latest series.

Furthermore, design for power supplies in natural convection operation requires capacitors that can handle higher temperatures. Rubycon will continue to develop such products while maintaining long life operation. We also plan to continue to develop capacitors that are not only optimized for high temperature but can also be stable across a broad temperature range.

Conclusion

AE capacitors are capacitors which combine such characteristics as high voltage resistance, high capacitance and safe performance which are required for input smoothing capacitors of power source input circuits / devices. AE capacitors are relatively small in size and low in cost compared with other types of capacitors of the same capacitance and, for this reason, AE capacitors are broadly used for various power source input circuits / devices.

Moreover, an application range and use of AE capacitors has been expanded each year, and the usage of AE capacitors has spread broadly under such a severe environment as onboard electronic devices. Rubycon shall continue its commitment to develop and offer new capacitors that meet the need for the expanding power market.

*This is an article which was published in the column of High Technology in Dempa Shimbun

published on 23rd August 2018.