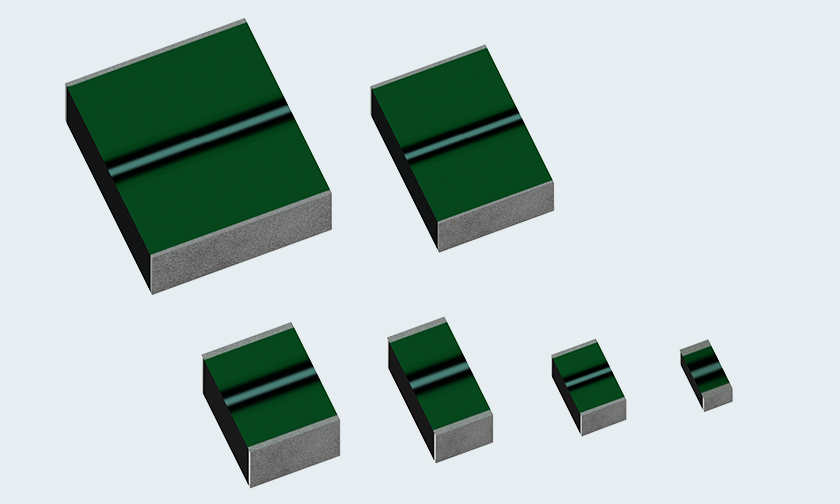

Polymer Multi-Layer Capacitors (PMLCAP)

- Features

- Series List / Series Chart

- Design Support

- Documents

- FAQ

A surface-mounted capacitor with excellent characteristics cannot increase the capacity, but PMLCAP is small and has a large capacity, and has excellent electrical characteristics and usability.

It is a capacitor that can deliver the optimum solution to the circuit that is difficult to use with a ceramic capacitor, does not satisfy the characteristics, etc.

Introduction of PMLCAP “MU”series

PMLCAP laminated-part formation method

Animation of the manufacturing process

Suitable for audio circuit. Replacement from ceramic capacitors(MLCC)

Suitable for sensor circuit. No piezoelectric effect of ceramic cap(MLCC)

No squeal occurs with LCD driver and DCDC converter

Suitable for RF circuit & PLL synthesizer circuit

No risk of short circuit, smoke or fire due to cracks

Series List

PMLCAP

| Type | Series | Details | Search | Features | General purpose | Moisture-proof | Rated voltage(Vdc) | Capacitance(μF) | Category Temperature Range | Series |

|---|---|---|---|---|---|---|---|---|---|---|

| Stacking Type | MU |

|

|

Standard |

◯ | 10~200 | 0.0001~22 | -55~125 | MU | |

| new MF |

|

|

Miniaturized |

◯ | 16~63 | 0.033~4.7 | -55~125 | new MF | ||

| MS |

|

|

85℃ 85%RH |

◯ | 10~50 | 0.001~2.2 | -55~125 | MS | ||

| NS |

|

|

60℃ 95%RH |

◯ | 16~63 | 0.001~6.8 | -55~125 | NS | ||

| new HPB |

|

|

Box Type RelatedVoltage 500Vdc,900Vdc |

◯ | 500・900 | 5~20・10~25 | -40~125 | new HPB |

Series Chart

Technical Note

Catalog

Product Specifications

Cautions for Proper Use

Environmental Information

FAQ

What is the service life of a PMLCAP?

The service life of a PMLCAP varies greatly depending on the conditions of use, particularly if it is used at a higher voltage than the rated voltage or in a hot and humid environment.

Please contact Rubycon in advance for further information.

Is voltage derating necessary if the PMLCAP is used in the category temperature range?

The dielectric material used in a PMLCAP has superior heat resistance. Therefore, voltage derating is not necessary.

How is the buzz characteristic?

One of the benefits of PMLCAP is very low buzz when AC is applied, due to the high adhesion between the layers.

Please try using PMLCAP in any of your circuits that require quietness.